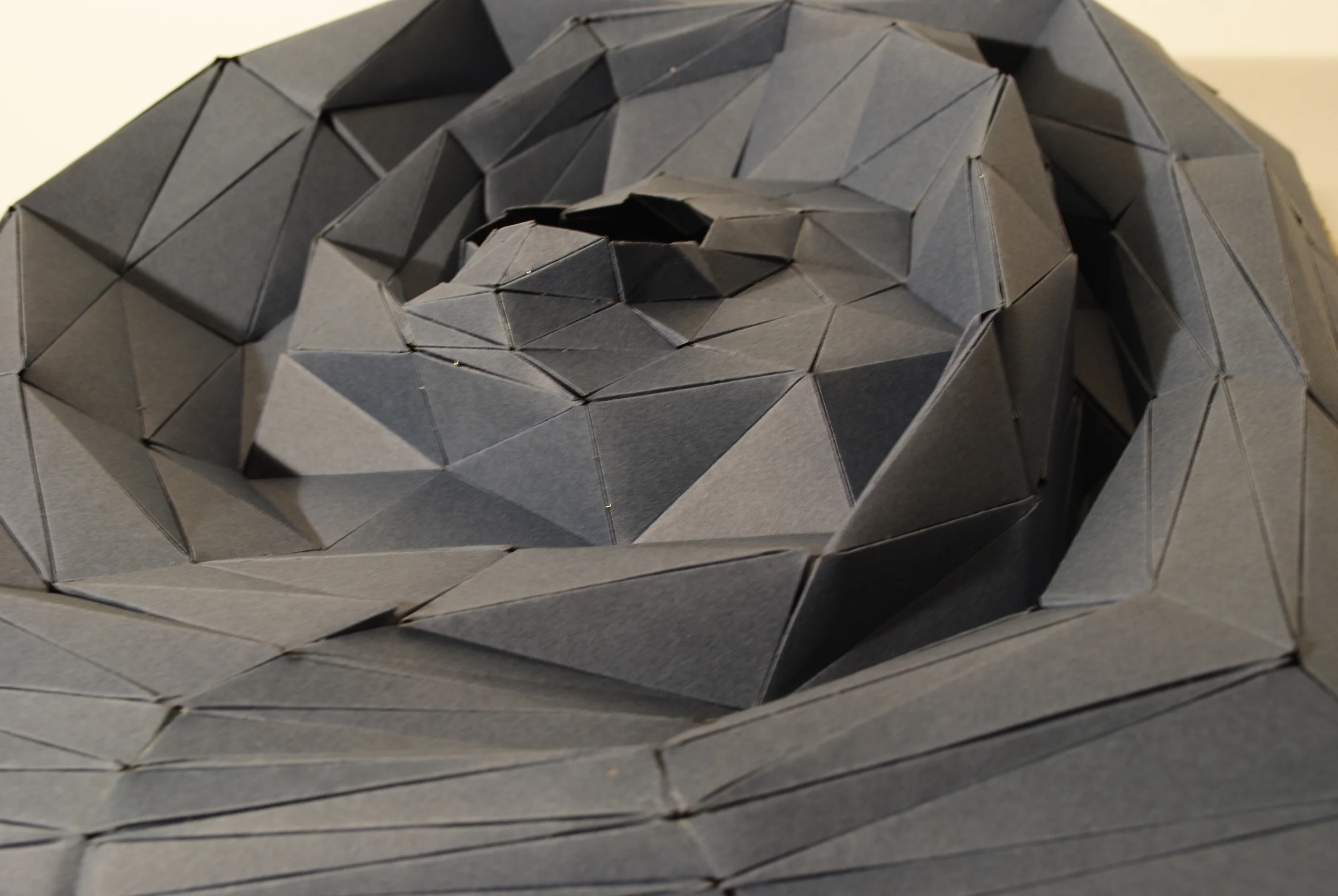

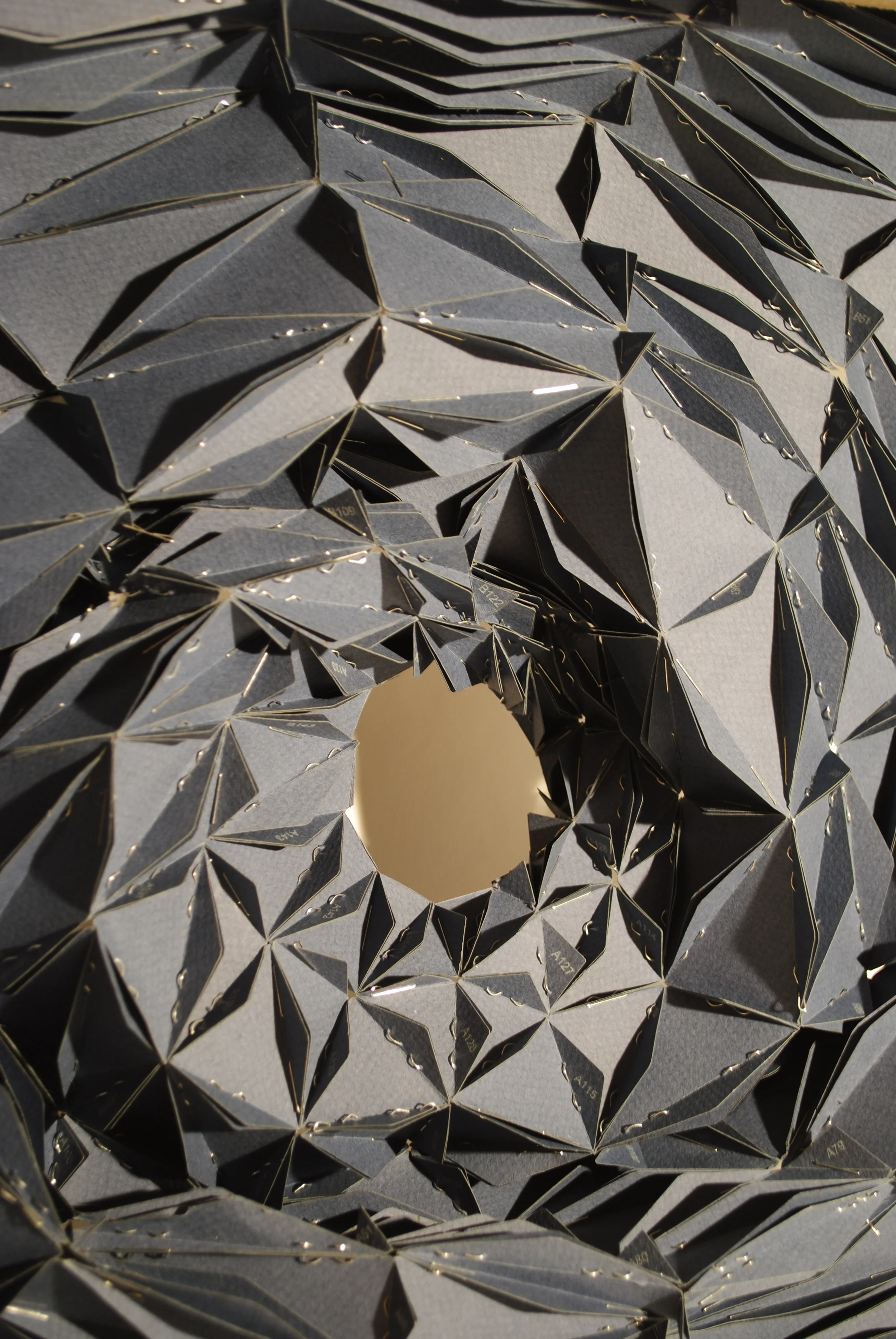

An advanced independent study focused on digital fabrication and fashion resulted in hybridizing disparate sectors of design. Using architectural and industrial design software and techniques to digitally create garments resulted in very unexpected results.

As the entire process is digitally designed, the starting point is to create a 3D body scan and design the garment around that. This results in a perfectly fitting garment with unusual silhouettes creating by digital modeling. The fabrication technique includes subdividing the dress into strips and applying a parametric tabbing solution to the edges which allow the dressed to be assembled without fasteners, seams, stitches or any other traditional garment manufacturing techniques. Embedding the logic of construction into the design of the piece united fashion and architecture in a unique and unusual way.

A series of sting mache lamps were designed with parametric modeling software and assembled by hand. The balance of digital design and hand fabrication allows for a beautiful object. The precision of the location of the string and the path it follows is parametric and the hand craft of making are in perfect harmony.

The making of objects is a passion.

Hand fabricated objects can be created from everyday amenities, such as the interior of a hollow core door and scrap tile and flooring.

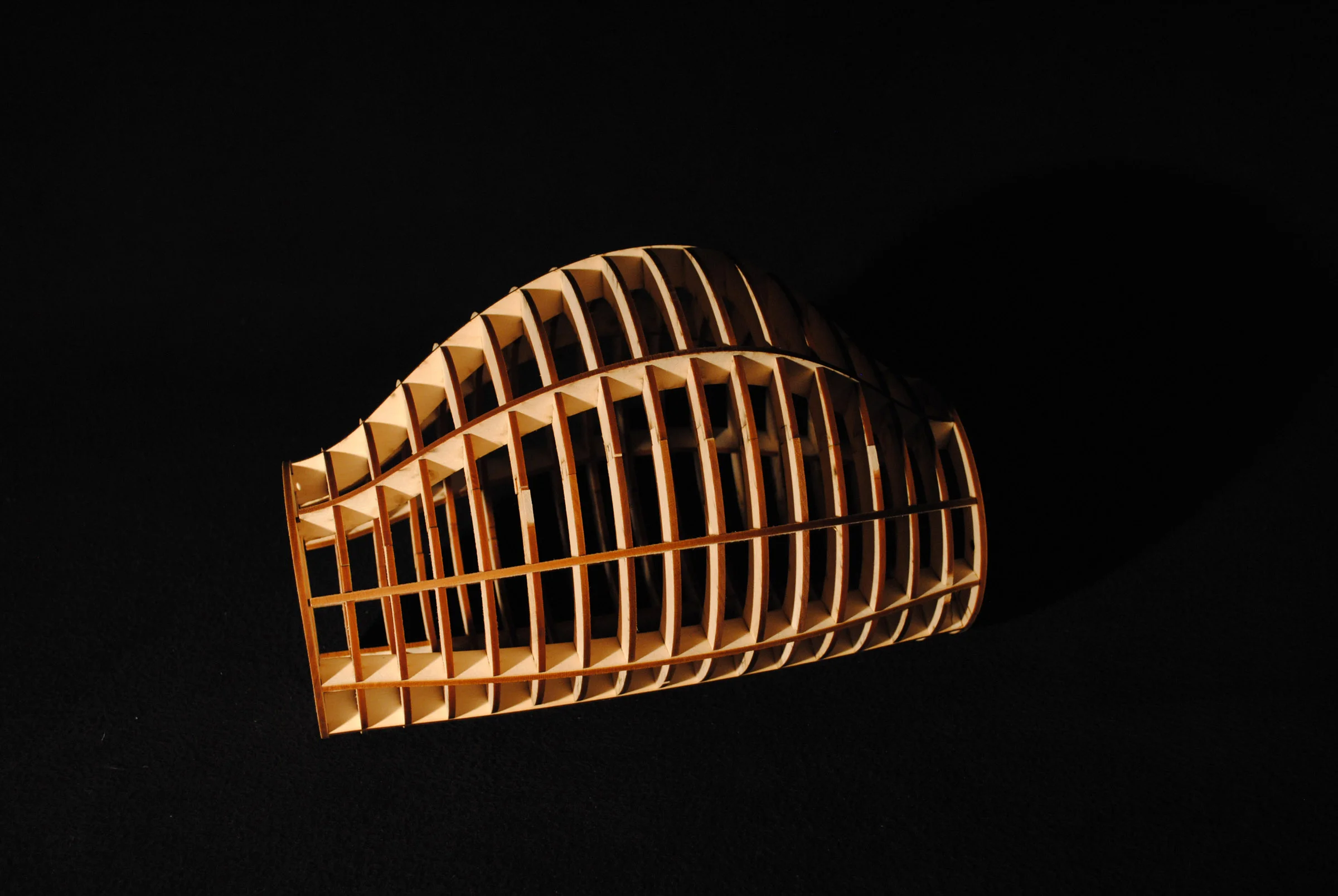

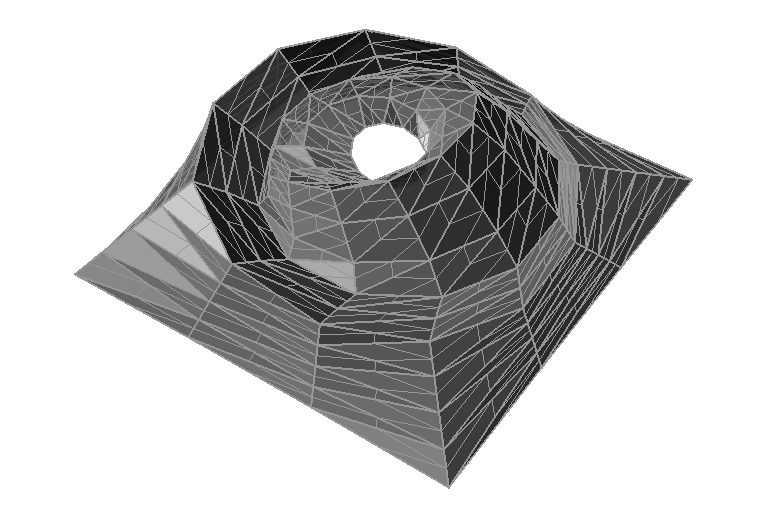

Digitally designed objects can be a simple as a flatpack, waffle form or as complex as a tessellated square panel. There is beauty in both the simple and complex.

Hand drafting made up a majority of my early undergraduate education. The ability to craft a drawing to convey the appropriate information in a clear and elegant way is a skill to be honed.

Sketching as seeing and understanding architecture relationships is important to understand space and form. During my semester in Florence with Syracuse University, this was an essential, daily activity that helped develop the concept of sketching as seeing and thinking.